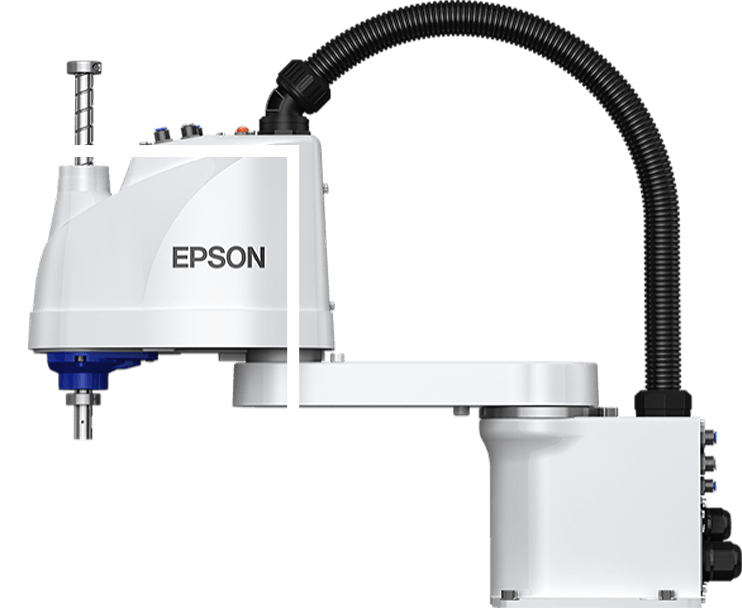

We Have The Latest

ROBOTS

SERVICES WE OFFERED

Services We Offer

Supply Automation

Supply leading edge automation products

Technical Support

Technical assistance with projects as required

Wide Product Selection

Provide advice on product selection

Training Support

Training and exercises

INDUSTRIES WE SERVICE

Industries We Service

Manufacturing

Medical

Aerospace

Special Purpose

Food and Beverage

Nuclear Science

Renewables

Product Packaging

COMPANY THAT TRUST US

Company That Trust Us

CONTACT US

Get In Touch With Us

Call us

Email us

sales@motion-solutions.co.nz

Working Hours

9am to 5pm Monday to Friday with 24hr Breakdown Service

Christchurch Warehouse

Level 3

112 Tuam Street,

Christchurch 8011

Press Release

Read Our Latest Articles

Strong Focus in Innovation

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form, by injected humour, or randomised words which don’t look even slightly believable. If you are going to use a passage of Lorem Ipsum, you need to be sure there isn’t anything embarrassing hidden in the middle of text.